A division of Andronaco Industries, PureFlex is a world-leading manufacturer of high performance Fluoropolymer and Composite products and technologies. We specialize in the manufacture of fluid handling and sealing products specifically designed for chemical, pharmaceutical, and ultra-pure related industries.

Since 1994, we have earned a reputation for creating flow solutions that are truly different. We create innovations—products that serve demanding applications better than before. PureFlex excels in its service, is aggressive in its technology, bold in its vision, and responsible in its regard for safe and dependable products.

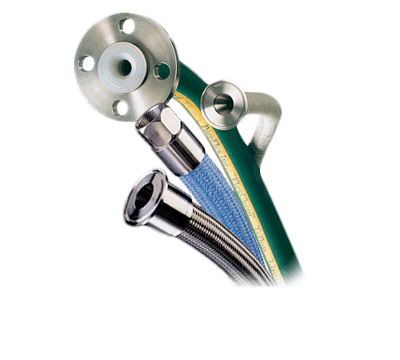

PureFlex products include FlexChem chemical-resistant hose, Durcor advanced structural composite piping, PureFlex composite valves, Task-Line chemical-resistant gaskets, and PureSite FEP sight glasses.

For more information, please visit PureFlex.