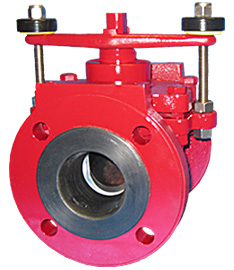

ChemValve offers lined plug and check valves in a wide variety of sizes and lining materials. Both valve styles offer injection-molding linings, which enables ChemValve to mechanically lock in the liners, whereas other designs use expanded-tube linings, which can create thin spots and stress concentrations. ChemValve’s method produces a consistent, predictable lining thickness very resistant to mechanical and vacuum stresses.

- Available in 1″-8″ sizes

- ANSI Class 150 raised-face flanged end connection

- Available in Polypropylene, Kynar® (PVDF), FEP-Teflon®, PFA-Teflon®, and GRPFA liner materials

- Rated at 275 PSIG up to 100°F, and 150 PSIG up to the temperature capability of the liner

- Rated for full vacuum service

- Adjustable Chevron PTFE packing

- Replaceable ball-valve style seats which take the wear off of the plug, and give the added benefit of a plug valve with lower turning torques than comparable valves, and replaceable without ever taking the valve out of the pipeline

- Simple valve and packing adjustment using just a pair of pliers.. no special tools or training required

- Thicker plastic liners, 0.125 inches minimum

- Longer service life

- Wide range of actuation options available

- Acrylic primer external finish standard, other coatings available

For more information, please visit ChemValve.